APPLICATIONS FOR ROLEC'S NEW ALUDOOR INDUSTRIAL ELECTRONIC ENCLOSURES

ALUDOOR: NEXT GENERATION INDUSTRIAL ELECTRONIC ENCLOSURES

New aluDOOR (IP 66, IP 67, IP 69K) has built on our previous design successes and taken diecast aluminum industrial enclosures to the next level. At the heart of this evolution are important design details that stand out as crucial differentiators.

Like ROLEC’s other diecast aluminum enclosures, aluDOOR is designed to go anywhere – on walls, machines, bulkheads – to suit a broad spectrum of industrial electronics applications. But this versatility hasn’t diluted the design ethos. Quite the opposite: it has reinforced it.

Advanced aluDOOR is ideal for applications as diverse as factory automation, sensors and detection, ship technology, railway systems, machine control, robotics and flow metering. All these can be challenging environments so aluDOOR’s ‘lid closed’ installation protects the electronics and the seal (a continuous foamed-in polyurethane gasket that provides superior ingress protection because it has no join). Yes, there are other ROLEC housings that offer ‘lid closed’ installation. But aluDOOR is the future, not least because of its new hinge design…

ALUDOOR’S SUPERIOR NEW HINGES

Advanced aluDOOR’s key feature is its new stronger hinges. Many of our existing models, such as the premium aluCASE, already feature either:

- plastic lid retaining straps – mounted internally to protect them and to enhance the aesthetics

- external hinges, which offer a stronger solution.

In fact, aluCASE offers both options. But aluDOOR features a completely new concealed hinge design which encompasses the benefits of both: all the strength of a metal hinge, with all the smart aesthetics of a small, compact retaining strap.

These hinges allow the recessed (or unrecessed) lid to open 100° for easier access. All the lid screws and threaded inserts are A2 stainless steel for added protection against corrosion. Fitting the lid is quick and easy. The lid with integrated hinge pin is pushed into place then secured with two tamperproof Torx T25 (M5) screws. Once closed, the lid is then locked down with two more T25 screws. All the lid and mounting screws are concealed beneath smart extruded aluminum trims.

APPLICATIONS: EXAMPLES OF CUSTOMIZED ALUDOOR ENCLOSURES

It doesn’t take much customization to transform a standard aluDOOR enclosure into the perfect housing for your industrial electronics. The finished enclosures can go from your Goods In directly to your production line. Here are some examples…

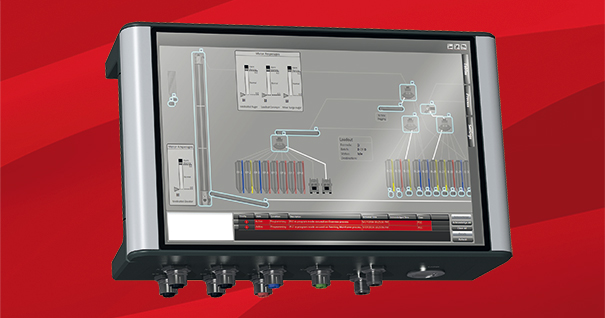

This process control unit retains the standard colors of anthracite (RAL 7016) with matt silver aluminum trims. Apertures have been machined for the cable glands (accessory). From there, it is simply a matter of adding the touchscreen display.

And this wireless unit is even simpler. It’s based on the ADO variant with a flat lid – no recess – and retaining the standard anthracite and silver color scheme. The only customization required is:

- printing the legends and wireless symbol

- machining apertures for the cable glands, LEDs and aerial.

This gas meter takes the branding a stage further. It was created using an ADF recessed lid version of aluDOOR and machining three apertures for the plastic cable glands. The three-color livery was achieved by:

- specifying yellow as a custom color for the main case body

- specifying the aluminum trims in black rather than the standard silver

- fitting a gray and red membrane keypad and display.

This military electronics equipment also utilises the ADF recessed-lid variant. Simple machining and custom anthracite trims to match the main case body create a ready-to-use housing in military non-reflective drab. It proves again that the journey from off-the-shelf case to fully customized enclosure can be quick, convenient and cost-effective.

SPECIFYING CUSTOMIZED DIECAST ENCLOSURES

Ordering fully customized versions of new aluDOOR (and any other ROLEC enclosures) is quick and easy. And all customization is done in-house so ROLEC is fully accountable for the high and consistent quality of your enclosures from start to finish.

Customization services include CNC machining, engraving, laser processing, display windows, digital printing of legends, logos and graphics, and assembly/installation of accessories. Find out more here.

View aluDOOR range >>Further Reading

- ROLEC’s Full Range Of Aluminum Electronic Enclosures. View them here…

- Which Industrial Electronic Enclosures? Aluminum Or Plastic? Read more…

- Six Key Questions To Ask When Specifying Diecast Electronic Enclosures. Read more…

- Specifying Customized Industrial Electronic Enclosures. Read more…

- How Best To Color-Code Or Brand Your Industrial Electronic Enclosures. Read more…

Get Expert Technical Advice

Seemingly similar industrial electronic enclosures can offer very different technical benefits so it pays to get expert technical advice. With our decades of experience, we can help you to specify the best standard and customised enclosures for your electronics.

Contact us now and tell us your requirements.