WHICH DIECAST ALUMINUM ENCLOSURES FOR MY INDUSTRIAL ELECTRONICS?

FAILURE IS NOT AN OPTION

Are you specifying the right kind of protection for your electronic enclosures? Challenging industrial and outdoor environments have a nasty habit of punishing under-specification – with potentially expensive consequences.

Heavy industry and Mother Nature will show no mercy to your fragile electronics if there’s a gap in your armour. Getting it right means ensuring your enclosures can withstand hard knocks, dust/water ingress and corrosion.

There are also other important practicalities to consider such as weight and price – though savings on the latter are no comfort if your device’s survivability is compromised because you specified the wrong housing.

WHICH IP-RATED ALUMINUM ENCLOSURES ARE MORE WATERTIGHT?

That’s a loaded question…but we deliberately wrote it that way to alert you to a critical consideration: watertightness is not a binary concept. It’s not a simple yes or no. There are other factors at play – such as force/pressure and whether the enclosure must survive immersion.

This is why the IP ratings scale is not as simple as it appears at first glance. Whilst higher numbers may suggest superior levels of protection, there’s much more to it than that. Here are some examples…

Diecast aluminum enclosures such as premium aluCASE and new aluDOOR offer different levels of protection. For instance, they are both rated to:

- IP 66 – complete protection against dust ingress, protection against temporary flooding (such as in heavy seas) – the test involves the enclosures withstanding 100 litres of water per minute at a pressure of 100 kPa at a distance of three metres.

- IP 67 – complete protection against dust ingress; protection against immersion in water (150-1,000 mm deep) for at least 30 minutes.

- IP 69K – complete protection against dust ingress; protection from high-pressure water jets and steam cleaning.

Find out more here about IP ratings >>

WHICH ALUMINUM ENCLOSURES SHOULD I SPECIFY?

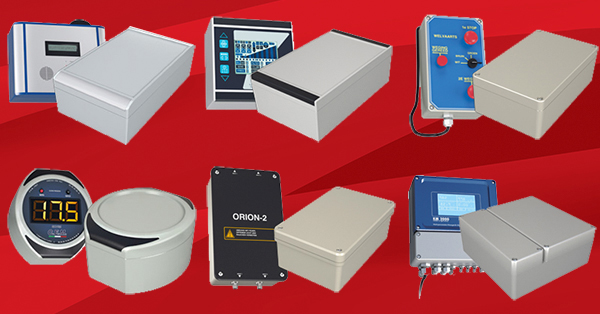

ROLEC offers plenty of choice – 10 models , with combinations of different technical features to suit specific applications. Ask us about:

- ‘lid closed’ installation (to prevent dust/water ingress during fitting, maintenance and removal) versus space-saving single channel fixings

- new extra-secure lid fixings with stainless steel screws and stainless steel threaded bushes (aluDOOR IP 66, IP 67, IP 69K)

- fixings concealed under trims (some models offer a choice of trims as standard for color-coding or branding)

- enclosures in industry-standard sizes (aluPLUS IP 66, IP 67)

- multivariable construction to give a wide choice of sizes (aluNORM IP 66, IP 67)

- enclosures with two internal chambers (aluTWIN IP 66)

- built-in RFI/EMI shielding, no gaskets required (conFORM IP 66, IP 67; conTROL IP 66, IP 67)

- recessed lids for membrane keypads, front panels or product labels

- enclosures with an extra-deep lid recess to protect large buttons (conTROL IP 66, IP 67).

ALTERNATIVES TO DIECAST ALUMINUM ENCLOSURES

As good as diecast aluminum is, there may be times when another material would be better for your application. Glass-fibre reinforced polyester (GRP) housings are well suited to environments where chemicals can pose a risk. GRP is tough, weather resistant and offers excellent protection against a wide range of chemicals.

Our GRP enclosures include polyTOP (IP 66, IP 67) and polyDOOR (IP 66), which has a hinged lid. Both models offer a choice of lid screws as standard: slotted head; square, triangular (to prevent tampering) and hand screws (for fast access).

The rise of Industry 4.0 has meant that plastic enclosures are becoming increasingly prevalent in the new generation of smart factories. Traditionally, ABS (Acrylonitrile butadiene styrene) was the go-to thermoplastic for many electronic enclosures but it has now been superseded by UV-stable ASA (Acrylonitrile styrene acrylate, aka Acrylic styrene acrylonitrile) or an ASA-PC blend that features polycarbonate for added strength.

We offer five different models of plastic enclosure. They include:

- technoDISC (IP 66, IP 67) – an ASA+PC version of our aluDISC ‘round’ aluminum enclosures; technoDISC is lighter and more cost-effective but, unlike aluDISC, there is no IP 69K option. (And nor does technoDISC offer a transparent lid variant as standard – aluDISC does.)

- technoPLUS (IP 66, IP 67, IP 69K) – advanced ASA enclosures for outdoor electronics. They are specially designed for installation on masts and poles thanks to a unique attachment that allows horizontal or vertical mounting. This feature is available as standard only on this model – there is no off-the-shelf equivalent in the diecast aluminum enclosures range.

SPECIFY CUSTOMIZED ENCLOSURES FOR INDUSTRIAL ELECTRONICS

All ROLEC enclosures – aluminum, GRP or plastic – can be supplied fully customized ready for the installation of your components. They can go straight to your production line. Customization services include CNC machining, laser processing, engraving, powder coating, painting, printing (digital and silk screen), RFI/EMI shielding, display windows, membrane keypads and assembly of accessories.

FURTHER READING

- Which Industrial Electronic Enclosures? Aluminum Or Plastic? Read more…

- Six Key Questions To Ask When Specifying Diecast Electronic Enclosures. Read more…

- Specifying Customized Industrial Electronic Enclosures. Read more…

- How Best To Color-Code Or Brand Your Industrial Electronic Enclosures. Read more…

GET EXPERT TECHNICAL ADVICE

Contact ROLEC for expert advice on specifying the best enclosures for your electronics. Our engineers can outline all the technical benefits of diecast aluminum, GRP and plastic enclosures – and the best and most cost-effective ways to customise them.